How Much Do Butcher Block Countertops Cost?

Butcher block countertops have gained significant popularity in recent years, becoming a sought-after feature in both residential and commercial kitchens. Their warm aesthetic, durability, and versatility contribute to their desirability. However, before deciding to incorporate butcher block into a kitchen design, it is crucial to understand the factors influencing the cost of these countertops.

Understanding the cost of butcher block countertops involves considering several aspects, from the type of wood used to the installation complexity and any additional treatments or accessories. This article will delve into the various elements that contribute to the final price, providing a comprehensive overview to assist in informed decision-making.

Wood Species and Their Impact on Price

The type of wood used is arguably the most significant factor influencing the price of butcher block countertops. Different wood species possess varying characteristics in terms of hardness, grain patterns, and availability, all of which directly impact the cost.

Hardwoods: Hardwoods are generally denser and more durable than softwoods, making them a preferred choice for butcher block countertops. Popular hardwood options include maple, oak, walnut, cherry, and birch. Maple is a commonly used and relatively affordable hardwood, offering a light color and tight grain pattern. Oak, known for its strength and prominent grain, is another widely available and reasonably priced option. Walnut, with its rich, dark color and distinctive grain, is a more luxurious and expensive choice. Cherry is prized for its reddish-brown hue and smooth texture, also typically commanding a higher price point. Birch is a more economical hardwood alternative to maple, offering similar durability but potentially with more color variation.

Softwoods: While less common than hardwoods for butcher block, softwoods like pine and fir can be used. Softwoods are generally more susceptible to scratches and dents, making them less ideal for heavy-duty chopping and food preparation. However, they are significantly more affordable, making them an attractive option for budget-conscious projects or purely decorative applications. When using softwoods for countertops, it's often recommended to apply a durable sealant or finish to enhance their resistance to moisture and wear.

Exotic Woods: Exotic wood species, such as teak, zebrawood, or wenge, offer unique aesthetics and are often sourced from international locations. These woods typically come with a higher price tag due to their limited availability, specialized harvesting practices, and transportation costs. Exotic woods can introduce a distinctive visual element to a kitchen, but their cost and sustainability concerns should be carefully considered.

Wood Grade: The grade of the wood also impacts the price. Clear grades, which are free of knots and imperfections, will be more expensive than grades with more visible knots and character marks. The presence of knots and imperfections can affect the aesthetic appeal and, in some cases, the structural integrity of the butcher block.

The sourcing of the wood is also relevant. Sustainably harvested wood from responsibly managed forests may command a premium due to the ethical and environmental considerations involved. Consumers who prioritize sustainable building materials may be willing to pay more for wood certified by organizations like the Forest Stewardship Council (FSC).

Countertop Size, Thickness, and Construction Style

Beyond the type of wood, the dimensions and construction style of the butcher block countertop influence its overall cost. Larger countertops require more material, obviously increasing the price. Thicker countertops generally cost more due to the increased wood volume and enhanced structural stability.

Edge Grain: Edge grain butcher block is constructed with the edges of the wood strips facing up, creating a narrow, linear pattern. This is a commonly used and cost-effective construction style, offering a balance of durability and affordability.

Face Grain: Face grain butcher block features the broad surface of the wood strips facing up, showcasing the natural grain patterns. This style is often selected for its aesthetic appeal, but it is generally less durable than edge grain due to its susceptibility to knife marks. Face grain countertops are typically more expensive than edge grain.

End Grain: End grain butcher block is constructed with the ends of the wood strips facing up, creating a checkerboard-like pattern. This style is the most durable and forgiving for cutting and chopping, as the wood fibers absorb the impact of knives. End grain butcher blocks are typically the most expensive option due to the more complex construction process and increased material usage.

Customization: Custom countertops, including unusual shapes, sizes, and edge profiles, will typically increase the cost. Complex designs require more labor and specialized equipment, resulting in higher fabrication costs. Customized features may include integrated sinks, drain boards, or unique edge treatments.

The thickness of the countertop is another crucial factor. Thicker butcher blocks require more material and are generally more durable, commanding a higher price. Common thicknesses range from 1.5 inches to 4 inches or more. Thicker countertops provide a more substantial and luxurious feel.

Fabrication, Finishing, and Installation Costs

The fabrication process, finishing techniques, and installation complexity all contribute to the overall cost of butcher block countertops. Fabrication involves cutting, shaping, and joining the wood to create the desired countertop dimensions and features. Finishing involves applying sealants, oils, or varnishes to protect the wood and enhance its appearance. Installation involves securing the countertop to the cabinets and ensuring a level and seamless fit.

Fabrication Costs: Professional fabrication services can range significantly depending on the complexity of the design and the skill of the fabricator. CNC (Computer Numerical Control) machining can provide precise cuts and intricate detailing, but it also adds to the cost. Hand-crafted fabrication, while more traditional, can also be expensive due to the labor involved.

Finishing Costs: The type of finish applied to the butcher block will also impact the cost. Food-safe mineral oil is a common and relatively inexpensive option for maintaining butcher block surfaces used for food preparation. Polyurethane finishes offer greater protection against moisture and stains but are not food-safe and require careful application. Professional finishing services ensure a consistent and durable finish, but they can add to the overall cost.

Installation Costs: Installation costs vary depending on the complexity of the project. Simple installations involving replacing an existing countertop with a similar-sized butcher block will be less expensive than complex installations involving significant modifications to the cabinets or plumbing. Professional installation ensures a secure and level countertop, preventing future problems such as warping or cracking.

Sealing: The type of sealant and the number of coats applied will affect the final cost. High-quality sealants provide better protection against moisture and stains, extending the lifespan of the countertop. Multiple coats of sealant may be necessary to achieve optimal protection.

Seams: If the countertop requires seams, the quality of the seam joint will affect the overall cost. Well-executed seams are virtually invisible and provide a seamless appearance. Poorly executed seams can be unsightly and prone to moisture damage.

Considering all these elements, the price of butcher block countertops can vary widely. It is crucial to obtain multiple quotes from reputable fabricators and installers to compare prices and services. Understanding the factors that influence the cost allows for informed decision-making and helps to ensure that the chosen butcher block countertop meets both budgetary and aesthetic requirements.

Maintenance should be considered as an ongoing expense. Butcher block requires regular oiling to prevent drying and cracking. The frequency of oiling depends on the usage and environmental conditions.

Ultimately, the decision to invest in butcher block countertops involves weighing the cost against the benefits. The warmth, durability, and aesthetic appeal of butcher block make it a desirable choice for many homeowners and business owners. By carefully considering the factors discussed in this article, prospective buyers can make an informed decision and choose a butcher block countertop that meets their needs and budget.

How Much Do Butcher Block Countertops Cost Angi

Butcher Block Countertops Ing Guide The Home

Sparrow Peak 25 In 1 5 Natural Wood Walnut Butcher Block Countertop 1525speuwal 72 At Com

How Much Do Butcher Block Countertops Cost Angi

Hardwood Reflections 4 Ft L X 30 In D Unfinished Birch Solid Wood Butcher Block Desktop Countertop With Eased Edge 1530hdbir 48 The Home

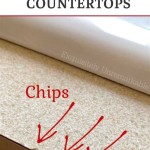

Butcher Block Countertops Pros And Cons To Consider Before Installation

Sparrow Peak 6 Ft X 25 In 1 5 Natural Wood Birch Butcher Block Countertop F1525spbir 72 At Com

Our Butcher Block Counter Top Review One Year Later

Custom Wood Butcher Blocks

Walnut Butcher Block Countertops Country Mouldings